| Symbol: | Ti |

| Melting point: | 1668'C |

| Electron configuration: | [Ar]3d24s2 |

| Atomic number: | 22 |

| Atomic mass: | 47.867±0.001u |

| Ore | Common Name | Formula |

|---|---|---|

| Oxides | Ilmenite | FeO,TiO2 |

| Rutile | TiO2 | |

| Titaniferrous Magnetite | Fe3O4,TiO2 | |

| Anatase | TiO2 | |

| Brookite | TiO2 |

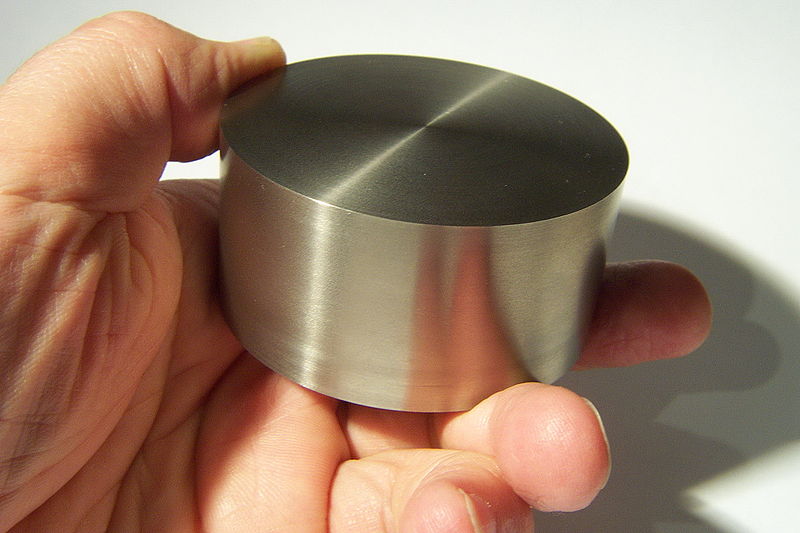

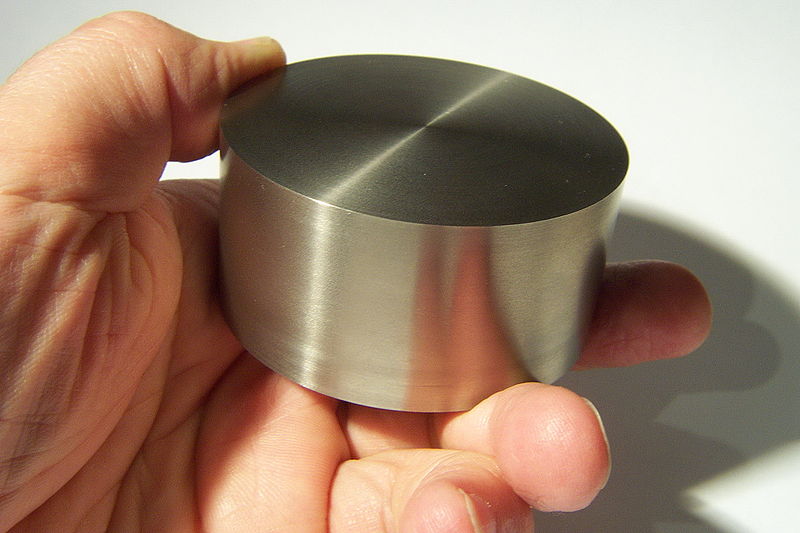

Titanium is a bright metal with grayish white color. It is similar in properties to tin. Titanium occurs as titanium oxide in nature. It is found as titaniferrous magnetite in most of the magnetite deposits. The important minerals of titanium are ilmenite, rutile. Titanium also occurs as silicate in the form of calcium titanium silicate. The minerals like ilmenite and rutile are found in basic igneous rocks. Due to continuous weathering and heavy character of these minerals, these are found as sand deposits along river beds and sea beaches. Another mineral of titanium is leucoxene. It is found in pegmatite veins and beach sand deposits. The major producers of titanium minerals are U.S.A, Canada, Australia, Norway, India, South Africa, Finland, Brazil, Sri Lanka, Sierra Leone and Ukraine. The major producers of titanium metal are U.S.A, Russia, Germany, Japan and France. The minerals of titanium are also known as heavy minerals.

The minerals like ilmenite and rutile are formed in basic rocks and granitic rocks. Due to prolong weathering by river and wind, these minerals are carried away from parent rocks and deposited as the beach sand minerals. The wave action of sea waves and tidal waves also helped in concentration of these heavy minerals along some selected pockets. These minerals are also associated with heavy minerals like silmanite, zircon, garnete and monazite. Titanium is used for production of titanium ferroalloys. It is used in paints and chemicals. Ferrotitanium is used for production of special steel which are strong and corrosion resistant. These alloys are used in medical instruments. These are also used in heat exchanger tubes in power plants. Titanium alloy are used in aircraft and aerospace application.

The beach sand is concentrated and beneficiated. The minerals like ilmenite, rutile and zircon are separated by gravity separation process. The mineral ilmenite contains iron and can be separated by magnetic separation process. In the next stage, rutile is separated through mechanical sieving. The ilmenite minerals are cleaned and reduced in a rotary kiln in the presence of coal. The oxygen is separated out and the metallic concentrate remains. The metallic concentrate is smelted in an electric arc furnace. Small amount of limestone and coke is also added. Oxygen is blown into the furnace. The impurities join the slag phase and a thin slag is formed above the molten ferrotitanium. The molten ferrotitanium is removed and the slag is separated out. The ferrotitanium is put into casting for cooling. The ferrotitanium is used for production of special alloys.

The titanium metal is separated from ferrotitanium by electrorefining method. The electrolyte is a mixture of titanium chloride and sodium chloride. The ferrotitanium and titanium scrap are used as anode. The cathode may be of steel. The working temperature is 850'C. The current is applied and electrolysis is started. Slowly, the titanium is dissolved in the electrolyte and there is precipitation of titanium at the cathode end. The iron and other impurities remain unchanged. These impurities are removed from time to time. The composition of the electrolyte is also adjusted by addition of titanium chloride and sodium chloride. The titanium metal is deposited at the cathode end. It is separated carefully to avoid any contamination. The separated metal of titanium is cleaned and kept for future use. The cell used for electrolysis is made up of graphite. The graphite cell helps in reduction of contamination of iron, silica and other impurities. The anode is covered with a porous diaphragm. The cathode is also covered with a porous diaphragm.

Titanium is a ferritic stabilizer. It is also a very strong carbide forming elements. The titanium carbide increases the wear and abrasion resistance of the steel. It is a strong grain refiner. When titanium carbide is added to stainless steel to improve the corrosion resistance of the alloy, the alloys of titanium are very good alloys with resistance of corrosion and fatigue. A thin impermeable oxide film is formed on the surface of the alloy. Major alloys with titanium are used in aerospace industries as The titanium metal has very high specific gravity and the melting point is of 1725'C. This character of titanium has helped in use of its alloys in jet engine constructions. Due to creep properties and fatigue strength of titanium, its alloys find large scale applications in aerospace industries. Like aluminium, titanium also provides coating of oxides with thick cover. It is used in chemical plants where titanium alloy resists attack of chemicals under extremely hostile conditions. It is used in production and storage units of acids, chlorides and bromides. The alloying elements like molybdenum, vanadium, niobium, silicon, copper, aluminium and iron are alloyed with titanium to produce quality alloys. A little amount of titanium added to copper can produce an alloy which is used in electrical contacts,non-sparking tools and springs. Very small amount of titanium, aluminium, vanadium and niobium are used for alloying addition in micro-alloyed steel. These are also known as high strength low alloyed steels. These steels are used in auto-mobile industries. These are also used in offshore pipeline production. These steels are used in bridges and dam constructions.