Extraction of Iron

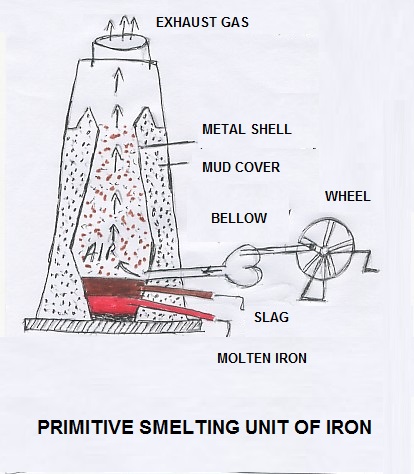

The primitive iron making technology passed from generation to generation through father to sons and grandsons. The primitive iron making process involved the preparation of the furnace using stone and clay. Its operation consisted of charging a mixture of iron ore, coal and lime stone pieces. The mixture was heated by burning of charcoal. Further, hot air was blown through the charge continuously. Slowly the carbon monoxide released due to burning of charcoal reduced the iron. Molten iron trickled down to the bottom of the furnace and a thick slag consisted of a lime stone and silica floats over the molten iron. The molten iron was collected into sand cups through a small opening through the furnace and again heated and hammered for removal of impurities. After that process, the iron was used for preparation of different articles. Iron is extracted are from iron ores in the blast furnace. The raw materials for extraction of iron are iron ore,coke and lime stone. The iron ores are crushed into small pieces in the crusher plant. The gangue materials are removed from the ore materials through the process of magnetic separation. To improve the metallic content are beneficiated in the beneficiation plant.

Then the blast furnace is filled with the layer of coke and iron ore in the alternative pattern up to the 2/3rd height of the blast furnace. The lime stone powders are injected into the blast furnace so that it mixes with the iron ore and coke. The ignition of the coke is started by the blowing of hot air into the blast furnace. The temperature is increased up to 2000' C. At this stage, the carbon react with the oxygen present in the iron ore. The process of reduction of iron ore contribute to the formation of metallic iron. The lime stone powder reacts with the silicate materials and other gangue materials to form a slag. The slag floats on the surface of molten iron. The metallic molten iron slowly trickles down to the bottom of the furnace. The molten iron is put into moulds to make Pig Iron. This slag which floats over the molten iron is removed through the inclined openings. Once the blast furnace is fired, it works for months.